Main Features

1.Totally EU streamlined design,Monoblock by welding robots & aparatus and stress relief process by Annealing treatment.

2.All machines are designed using SOLID WORKS 3D programming and made with enhanced ST44-1 quality steel with the latest technology.

3. MB8 Series are among the highest rated machines which will help you increase your productivity and keep costs at minimum levelwith its user friendly CNC controller and low cost hydraulic maintenance.

4. High quality and repetitive bending is obtained by using synchronized cylinders and valves.

5. Automatic axis referencing and calibrating when machine is turned on.

6. Rigid upper beam runs on 8-point bearings with bending precision of 0.01 mm

7. Well-known top and bottom tool brands are long lasting stiffened and provide precise bending.Silent high pressure pump.

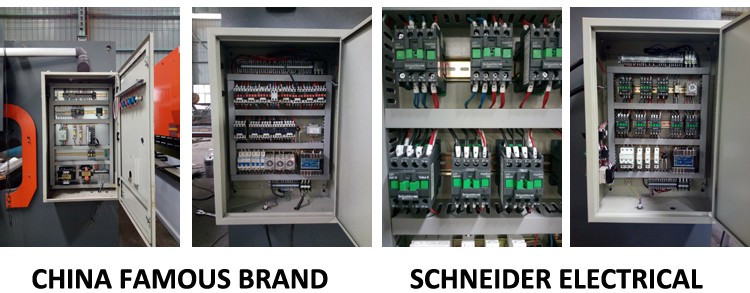

Electrical control system

1.Electric components and material are accord with international standard, safety and reliable, long life, and strong ant jamming capability.

2.Moving footpad attached.

3.Choosing high grade famous electrical control components.

4.The power of the machine is 3-phase AC380V

5.Main power way of motor has short circuit,overload,lack phase protection.

6.Operation buttons equipped on machine button stage, electric switch,pilot lamp equipped in electric box

7. Oil pump stop button as the total button of machine, when oil pump power off, whole machine stops working.

8.Inching control button and emergency stop button are installed on machine.

9.The synchronization of the slider travel of bending machine is mechanic synchronous unit in simple, stable and reliable structure with synchronous precision required by this machine. And generally, it can be used for long time while don’t need to be repaired frequently

Punch and die

1. A set of free charge upper and lower die attached with machine.

2. The lower dies are processed in different V-gutters to make operators select conveniently and it is equipped with lower die standing up structure, only need to put lifting roller chain on the slide lifting ear and lower die lifting ear, loose top formwork to raise slider to turn lower die then to select the location surface of V-gutter.

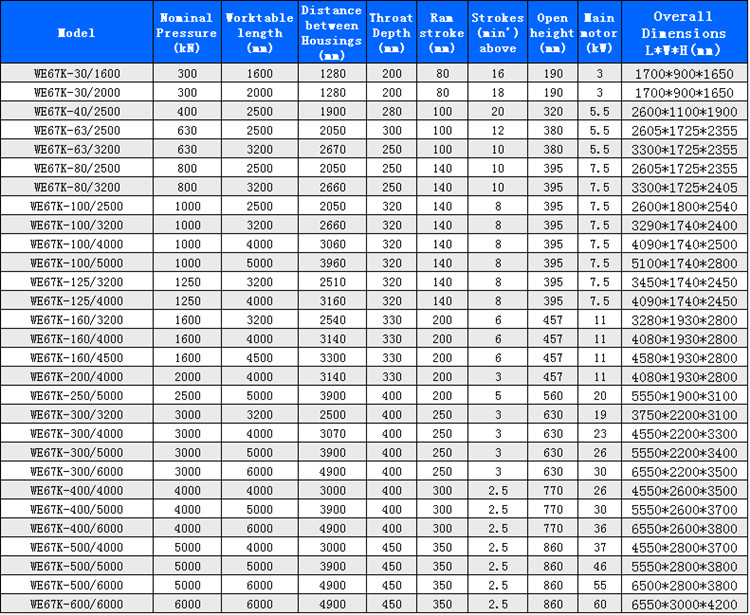

Technical parameters

Standard components:

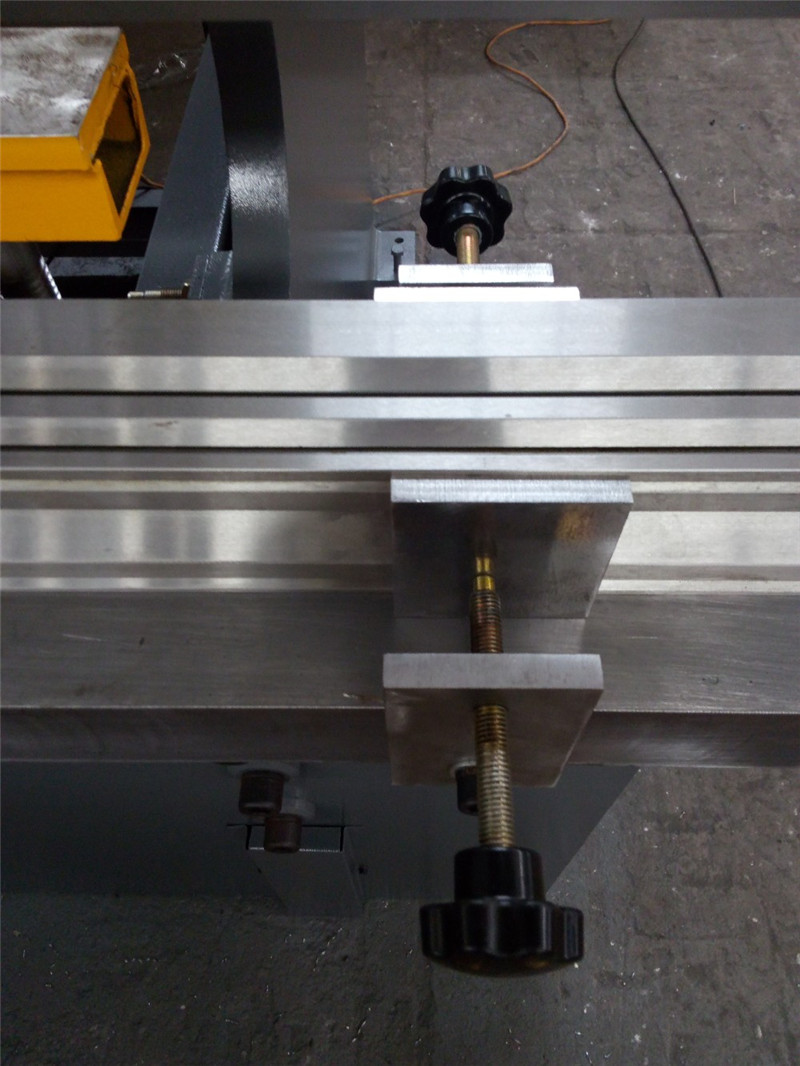

Detailed images

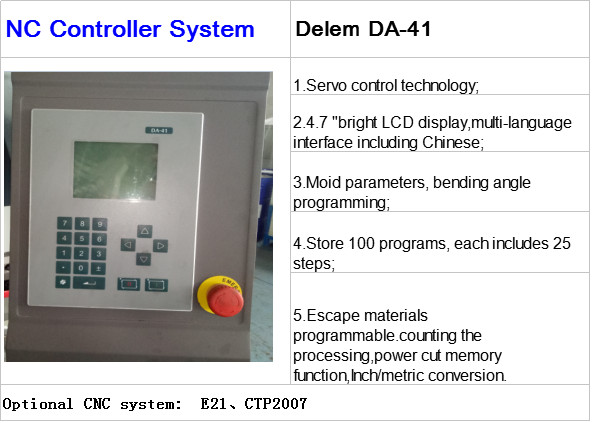

Press Brake Controller System: could be customized to meet your requirements:

Hydraulic Bending Machine Electrical System: China famous brand or Schneider system to guarentee our quality

Ultra-precision technical process

It ensures the straightness of the plate

Strict quality control

Every machine must be tested about 8 working hours before packaging

Expert in kinds of sheet metal processing machines, like bending machine, shearing machine, iron worker, hydraulic press, punching machine, duct manufacturing auto line, cutting machine and so on

*With an expert team in R&D for more than 20 years, occupied the work shop of over 30,000 square meters, ACCURL is able to support you with best quality machines

1. Technical solutions: we can provide technical solutions within one day.

2. Online video: show you machine working video in factory . ( update every month)

3. Installation service: this is available with all of our machines,

4.Training service: Our technician will teach you how to use our machines. As well, you may send your technician to our company to learn how to operate machines.

5. Quality guarantee: 1 year warranty, we provide lifetime service. We arrange final test before shipment, After making sure machine is the best performance, then make shipments.

6. 100% response rate: we will reply your question within 12 hours.

FAQ

1.Q:Are you a manufacturer or a trading company?

A:We are a manufacturer; We specialize in metal sheet metal steel processing equipment.

2.Q:How to choose a bending machine?

A:Please tell us the following information in detail:

- Material of plate:

-Max thickness:

-Max plate width:

-If possible: you can specify the model;

3.Q:Where is your factory? How can I get there?

A:You can fly to NanJing LuKou airport directly, we will pick you up in the airport. All our customers, both inland and abroad, warmly welcome to visit us!

4.Q:How do you ensure quality in the factory?

A:Quality culture.:We always attach great importance to quality control from the beginning to the end. Our factory has obtained ISO, CE certification.

5. Q:How can I pay?

A:You can pay by T/T, Western Union, MoneyGram, Paypal; 30% deposit; pay off the 70% balance before shipment.

6. Q:How long to produce ?

A:Delivery time:20 days.

7. Q:Minimum order quantity?

A:1 set

Quick Details

Condition:New

Place of Origin: Anhui, China (Mainland)

Brand Name: ACCURL

Model Number: WC67K-400T/5000

Machine Type: Press Brake

Raw Material: Steel Bar

Material / Metal Processed: Alloy

Power: Hydraulic

Automation: Automatic

Extra Services: End Forming

Certification: ISO 9001:2000

After-sales Service Provided: Engineers available to service machinery overseas

Name: cnc torsion bar hydraulic press brake with standard configuration

Color: Customized

Type: Metal Bender Tools

Usage: Metal Sheet Rolling Cutting Bending

Model: WC67K-400T/5000

Material: Stainess Steel

Warranty: 3 Years

Size: 5000*2200*3300mm

Weight: 26T

Application: stainless steel,carbon steel,me