Product Advantages

1.The main parts of the machine ensure quality and are provided by reputable and reliable companies.The motor and electronic system components are produced by Siemens and schneider of France

2.We use Germany schneider stroke button,which has good lasting stability, in the absence of any sudden drop, the schedule will remain stable or pause, so that we can avoid the occurrence of danger.

3.We use the same oil pump as the Chinese aircraft industry, which is produced by the Chinese company.We also use the German ECKERLER oil pump.

4.Both hydraulic systems and valves are from the U.S. OMG or Bosch of Germany.

5.Safety protection equipment: we have configured the magnetic doors on both sides of the machine to avoid any internal infiltration, while fully considering the safety of the workers.In the back of the machine, we provide three closing doors and the middle door can be moved.In this equipment, the power will close when the door opens, and the power will be switched on when the door is closed.Raster is a useful component in a dangerous position.

6.Our team has experience in CNC lathe.The sales machine includes the cybic 8 axis automatic electronic hydraulic synchro.We can use 3D and touch screens to design different axis control requirements.The numerical control system includes two kinds of synchronous and electric hydraulic synchronization, as well as the pressure braking of two kinds of connection of electro-hydraulic or mechanical.In many normal system brands such as estun/delem/cyb electromagnetic, it is always possible to find the most cost-effective method.

Main Features

1) The fuselage adopts the overall welding and overall machining structure, and ANSYS finite element analysis software is used to analyze the machine to ensure the precision of the machine tool.

2) Integrated control system imported feom Germany is adopted for the whole hydaulic system,to simplify the installtionof pipelines,and to ensure stable operation as well as simple and nice appearance of the machine tool.

3) The numerical control system adopts the special numerical control system of Italian ESA, Dutch DELEM or Switzerland cybco.

4) The workbench has the automatic compensation mechanism of the hydraulic automatic compensation system to realize the effective compensation without the blind area, and the bending precision is high, ensuring long-term stability.

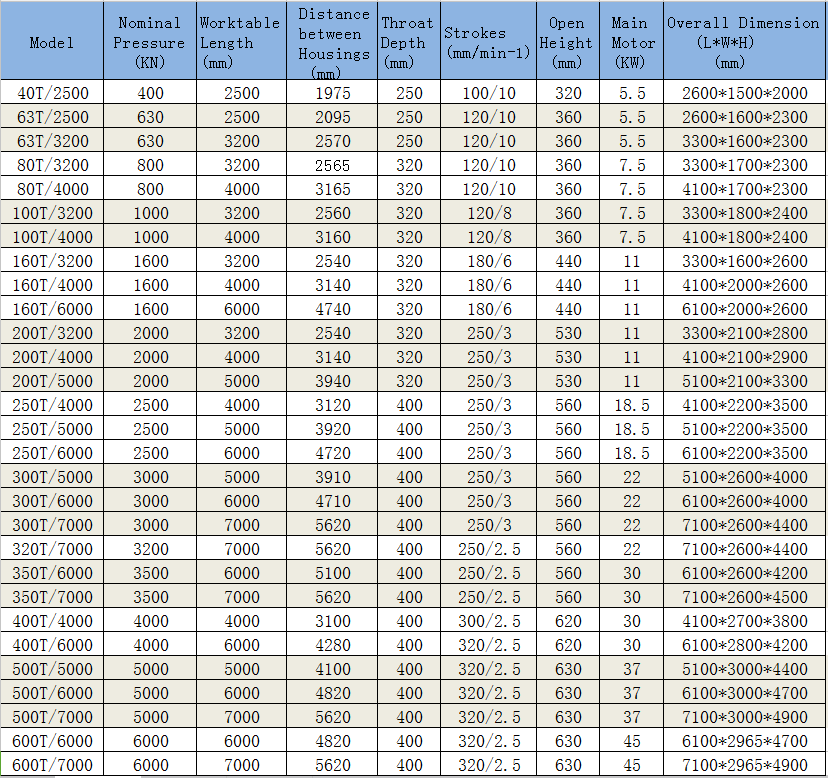

Main Parameters

Quick Details

Condition: New

Place of Origin: Anhui, China (Mainland)

Brand Name: ACCURL

Model Number: WC67K

Machine Type: Press Brake

Raw Material: Sheet / Plate Rolling

Material / Metal Processed: Stainless Steel

Power: Cnc

Automation: Automatic

Extra Services: Machining

Certification: CE

After-sales Service Provided: Engineers available to service machinery overseas

Nominal pressure: 1600KN

Table length: 3200mm

Column spacing: 2540mm

Throat Depth: 320mm

Strokes: 180mm/6min

Maximum opening height: 440mm

Main motor power: 11kw

Size: 3300*1600*2600