Performance characteristics

The E210-controlled CNC hydraulic bending machine provides a complete solution for the 2-axis traditional bending machine application. Provides versatile solutions for axis control of press beams and back pressure gauges as well as flexible I/O configurations based on state-of-the-art electronics. With its bright LCD display, it provides clear and simple control. Digital programming, angles at hand, tool and material parameters, can be summarized directly in the form.

The bending parameters can be selected by user-friendly cursor operation. Axis control supports servo control, 2-speed AC control, and inverter control. Depending on the application, you can choose both sides.

Positioning and one-sided positioning with spindle correction. Clear and simple operation can be achieved by tabulating the table on a bright LCD screen. Digital programming is user-friendly and guides the operator through all programming possibilities.

E210 CNC Controller Features

# Program memory of to 100 programs ,25steps per program

# Tool library:20 dies

# Conventional press brake control

# Angle programming and automatic bending position calculation

# Back gauge allowance compensation

# Dual servo system control

# Flexible I/O configuration

# Free group valve setting

# One side positioning

# Retract function

# Auto reference search

# Power-down memorization

# Mm/Inch

# Chinese/English

# Diagnosis function

STANDARD EQUIPMENTS

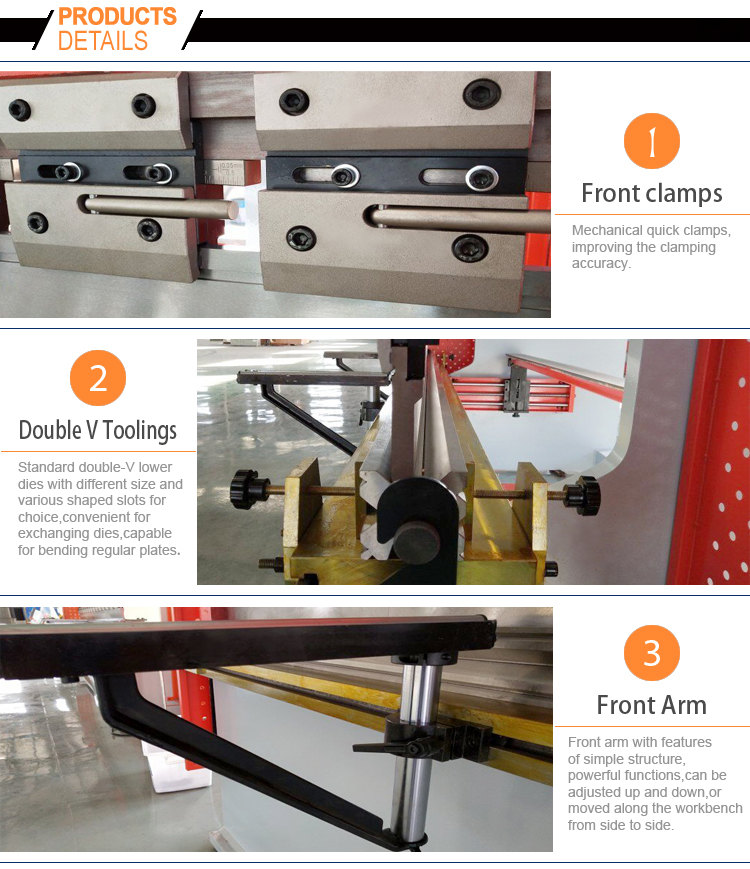

√ Height-adjustable and movable sliding front support arm.

√ The top and bottom tools are surface hardened by special treatment.

√ Netherlands DELEM E210 CNC system.

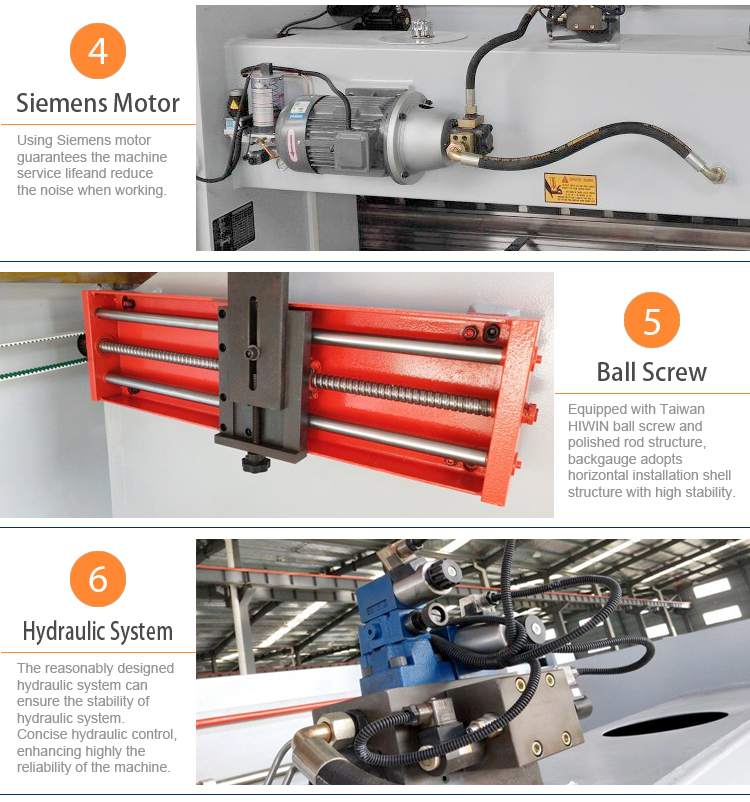

√ X-axis servo motor drive, timing belt + ball screw drive, high repeat positioning accuracy.

√ 3 can fine-tune the fingers.

√ Optional metric and inch measurement, Chinese and English display.

√ Foot pedals are produced according to CE standards and are suitable for single and multiple bends.

√ Cylinder and top beam cover

√ Pre-adjust electrical requirements based on customer's geographic area.

OPTIONAL EQUIPMENTS

√ Special strokes and throat depth provide additional advantages for deep bends.

√ CNC system E200, E300.

√ Special rear cover fingers can be added on the optional backgauge stroke.

√ Hydraulic oil heating and cooling.

√ Customized table width and bottom tool V opening.

√ Optional top and bottom tool lengths are different.

√ Box and pole bent special tools.

√ Laser avant-garde option.

√ WILA top and bottom tool clamping systems.

√ Rol 1, 2, 3, 4, 5 different top and bottom quick release clamping systems.

√ The tool cabinet is mounted on one side of the machine, keeping the tool clean and easily accessible.

√ The automatic sliding system automatically lubricates and it is highly recommended to extend the service life.

√ U-shaped special bottom tool for bending thick material.

√ Additional front support arms prevent waves on thin materials.

√ Customize the machine according to the customer's special parameters.

√ According to the customer's requirements, the electrical panel and/or controller can be mounted on the right side of the machine.

| No | Model | Pressure KN | Bending Leng (mm) | Columns Distance (mm) | Open Height (mm) | Throat Depth (mm) | Slide Stroke (mm) | Motor Power (kw) | Machine Size (mm) |

| 1 | 40T/2500 | 400 | 2500 | 1900 | 210 | 200 | 110 | 4 | 2600x1270x1980 |

| 2 | 63T/2500 | 630 | 2500 | 1900 | 235 | 250 | 120 | 5.5 | 2600x1360x2050 |

| 3 | 63T/3200 | 630 | 3200 | 2600 | 235 | 250 | 120 | 5.5 | 3300x1360x2050 |

| 4 | 80T/2500 | 800 | 2500 | 1900 | 320 | 320 | 150 | 7.5 | 2600x1400x2380 |

| 5 | 80T/3200 | 800 | 3200 | 2600 | 320 | 320 | 150 | 7.5 | 3300x1400x2380 |

| 6 | 80T/4000 | 800 | 4000 | 3100 | 320 | 320 | 150 | 7.5 | 4100x1400x2380 |

| 7 | 100T/2500 | 1000 | 2500 | 1900 | 330 | 320 | 150 | 7.5 | 2600x1400x2380 |

| 8 | 100T/3200 | 1000 | 3200 | 2600 | 330 | 320 | 150 | 7.5 | 3300x1400x2380 |

| 9 | 100T/4000 | 1000 | 4000 | 3100 | 330 | 320 | 150 | 7.5 | 4100x1400x2380 |

| 10 | 100T/5000 | 1000 | 5000 | 4100 | 330 | 320 | 150 | 7.5 | 5100x1400x2380 |

| 11 | 125T/2500 | 1250 | 2500 | 1900 | 330 | 320 | 150 | 7.5 | 2600x1400x2380 |

| 12 | 125T/3200 | 1250 | 3200 | 2600 | 330 | 320 | 150 | 7.5 | 3300x1400x2380 |

| 13 | 125T/4000 | 1250 | 4000 | 3100 | 330 | 320 | 150 | 7.5 | 4100x1400x2380 |

| 14 | 125T/5000 | 1250 | 5000 | 4100 | 330 | 320 | 150 | 7.5 | 5100x1400x2380 |

| 15 | 160T/2500 | 1600 | 2500 | 1900 | 400 | 320 | 200 | 11 | 2600x1550x2580 |

| 16 | 160T/3200 | 1600 | 3200 | 2600 | 400 | 320 | 200 | 11 | 3300x1550x2580 |

| 17 | 160T/4000 | 1600 | 4000 | 3100 | 400 | 320 | 200 | 11 | 4100x1550x2580 |

| 18 | 160T/5000 | 1600 | 5000 | 4100 | 400 | 320 | 200 | 11 | 5100x1550x2580 |

| 19 | 160T/6000 | 1600 | 6000 | 4800 | 400 | 320 | 200 | 11 | 6100x1550x2580 |

| 20 | 200T/2500 | 2000 | 2500 | 1900 | 435 | 320 | 200 | 15 | 2600x1650x2900 |

| 21 | 200T/3200 | 2000 | 3200 | 2600 | 435 | 320 | 200 | 15 | 3300x1650x2900 |

| 22 | 200T/4000 | 2000 | 4000 | 3100 | 435 | 320 | 200 | 15 | 4100x1650x2900 |

| 23 | 200T/5000 | 2000 | 5000 | 4100 | 435 | 320 | 200 | 15 | 5100x1650x2900 |

| 24 | 200T/6000 | 2000 | 6000 | 4800 | 435 | 320 | 200 | 15 | 6100x1650x2900 |

| 25 | 250T/2500 | 2500 | 2500 | 1900 | 435 | 320 | 200 | 18.5 | 2600x1750x3070 |

| 26 | 250T/3200 | 2500 | 3200 | 2600 | 435 | 320 | 200 | 18.5 | 3300x1750x3070 |

Quick Details

Condition: New

Place of Origin: Anhui, China (Mainland)

Brand Name: ACCURL

Machine Type: Press Brake

Raw Material: steel stainless sheet

Material / Metal Processed: Stainless Steel

Power: Cnc

Automation: Automatic

Extra Services: Ram stroke adjusted

Certification: CE

After-sales Service Provided: Engineers available to service machinery overseas

Name: Hydraulic press brake

Color: orange Hydraulic press brake

stop back: Manual Opertation

motor: servo motor

HYDRAULIC OIL: 46#

PUMP: GEAR PUMP

PUNCHING CAPACITY: YES

SHEET CUTTING: YES

ROUD STEEL CUTTING: YES

SQUARE STEEL CUTTING: YES